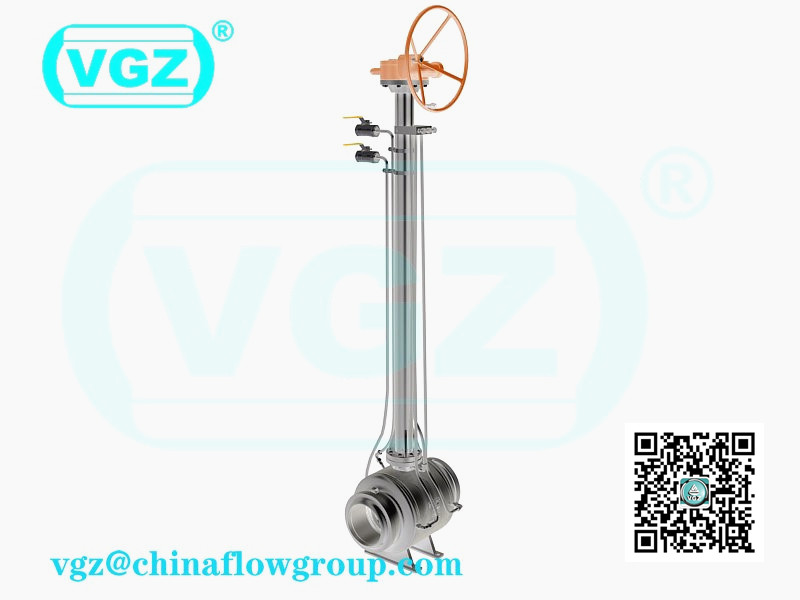

Fully Welded Ball Valve

VGZ Full Welded Ball Valve, Heating Ball Valve, Gas Ball Valve

Describe:

The fully-welded ball valve adopts forged material, welded body, instead of bolts and nuts, to aviod any potential leakage from body.

The forged body with regular structure and even thickness can avoid shrinkage cavities, pin holes, cracks, sand holes and other defects occurring to casting body valves.

Fully-welded ball valves can be spherical and cylindrical type. Usually the spherical type has only one welding seam on the body, the cylindrical type has two welding seam on the body.

Design features:

The ball valve are designed in accordance with ISO14313、API 6D;

Fire safe, anti-static and anti-blowout stem design;

Valve seat function DBB, DIB-1, DIB-2;

Optional extended bonnet;

Optional overlay stainless steel on body to seat surface and/or gasket container surface;

Be able to be used for underground installation without corrosion of interior parts, therefore, it is the best application for petroleum and natural gas line systems;

Service life up to 30 years.

Product Range:

Body material: low-temperature carbon steel, carbon steel

Nominal diameter:2"~60"(DN50~DN1500)

Pressure range:Class150~2500(PN10~PN420)

End connection: RF, RTJ, BW

Working temperature:-46℃~+200℃

Operation:Wrench, worm gear, electric , pneumatic , gas over oil actuator and electro-hydraulic actuator.

Email

Email