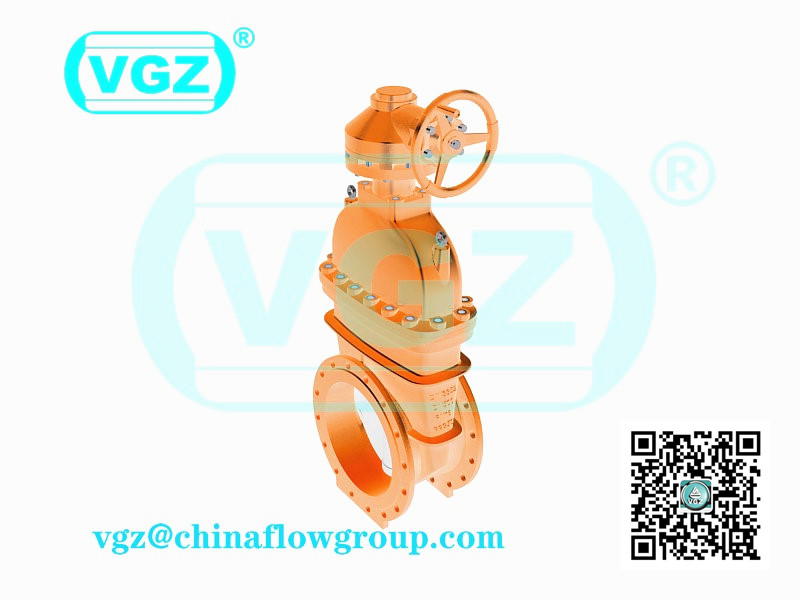

DIN 3202 F4 Gate valve

DIN 3202 F4 Gate valve

DIN 3202 F4 Gate valve

| Describe: |   |

|||||

| 1. Overall encapsulation: The valve adopts integral encapsulation, and its good geometrical dimensions ensure reliable sealing and long service life. 2, light weight: the valve body is made of ductile iron, light weight, easy to install and maintain. 3. Flat-bottomed valve seat: The bottom is made of the same flat-bottomed material as the water pipe, and the sealing is more reliable. 4. Corrosion resistance: The inner cavity is coated with non-toxic epoxy resin, which is anti-corrosion but can be used for raw drinks, and can be used in sewage system. 5, three "O" seal: the valve uses three three "O" seal design, can reduce the friction resistance when switching, greatly reducing the water leakage phenomenon is light and durable. |

||||||

| Design features: | ||||||

| Design criteria: DIN3352,DIN3202 F4 AWWA C509, CJ/T217 Smaller flow resistance design Switch torque is small No direction restrictions on the flow direction of the medium The seal is stable and can be applied to various working conditions for a long time. The valve has an upper seal design The stem is sealed with flexible graphite and graphite packing. Pressure seal structure Solid gate design Dark stem valve stem design Jacket insulation design |

||||||

| Product Range: | ||||||

| Body material: carbon steel, ductile iron, stainless steel, alloy steel Caliber: 2"~80" (DN50~DN2000) Connection method: RF, RTJ, Pressure range: Class75 – 150 (PN6~PN20) Working temperature: -46 ° C - +120 ° C Mode of operation: handle, worm gear, electric, pneumatic, electro-hydraulic, electric steam, etc. |

||||||

Email

Email